Closed Loop Cooling Systems

Closed-Loop Cooling Systems – Engineered Thermal Control for Reliable Ozone Generation

Overview

Efficient cooling is essential for the stable performance and extended lifetime of high-power ozone generators.

Longking EnTech Europe designs and manufactures closed-loop water cooling systems specifically engineered to maintain precise thermal conditions in industrial and municipal ozone plants.

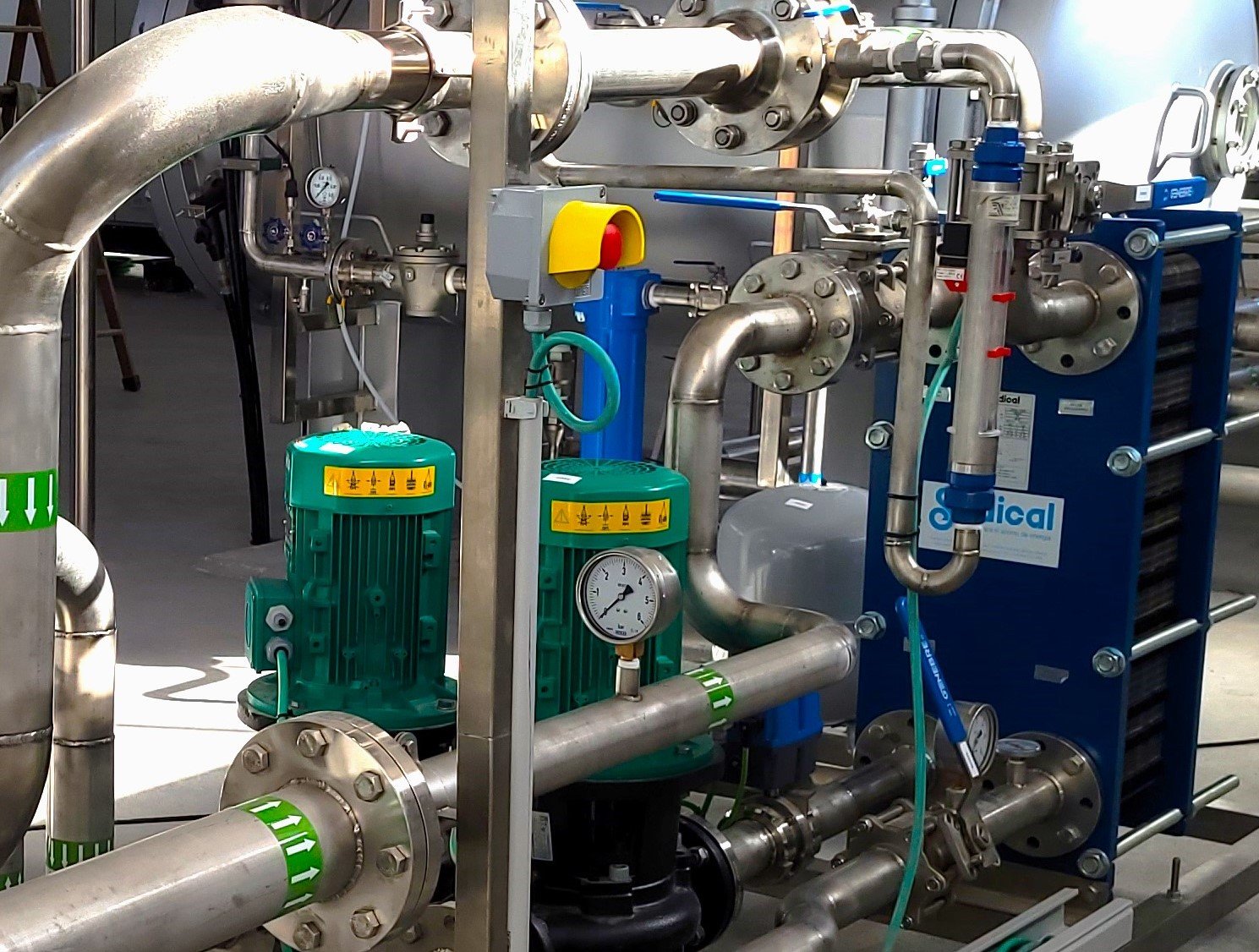

Each cooling circuit is fully self-contained, combining high-efficiency heat exchangers, redundant pumping systems, and automated thermal regulation to ensure reliable operation under varying load and ambient conditions.

Design & Functionality

The Longking Closed-Loop Cooling System is designed to dissipate the heat generated by ozone production and maintain a constant operating temperature, guaranteeing electrical stability, ozone yield efficiency, and equipment protection.

System configuration includes:

Plate Heat Exchanger: Provides efficient thermal transfer between process and cooling water circuits.

Dual Impulse Pumps (Hot Side): One pump in operation and one in standby for full redundancy.

Flow Rotameter (Cold Side): Enables visual flow control and calibration.

Thermometers (Hot & Cold Side): Continuous monitoring of inlet and outlet temperatures.

Pressure Gauges: Verifies circuit integrity and ensures safe operating pressure.

Gas Purge Line: Removes trapped air or gases to maintain circulation efficiency.

Expansion Vessel: Absorbs pressure fluctuations and thermal expansion.

Isolation Valves: Allow easy maintenance and loop isolation without system shutdown.

This configuration ensures stable, low-maintenance operation and protects critical components of the ozone system.

Thermal Engineering & Heat Exchanger Design

Each cooling system is individually engineered according to the thermal load and operating environment of the ozone plant.

Longking applies precise thermal calculations and hydraulic balancing to size every component of the loop.

Key design variables include:

Plate Number and Geometry: Selected to optimize heat transfer coefficient and minimize fouling.

Thermal Length & Pressure Drop: Adjusted for system stability and efficiency.

Material Selection: Stainless steel AISI 316L or titanium for corrosion resistance and long life.

Joints & Connections: Configured for compact integration with ozone generator skids.

This tailored approach guarantees efficient heat dissipation, minimal energy loss, and long-term performance even in harsh environmental conditions.

Intelligent Cooling Control

To maintain constant thermal equilibrium, Longking’s cooling systems incorporate automatic control and monitoring.

Main control functions:

Temperature-based pump sequencing and speed regulation.

Flow and pressure monitoring with alarms and shutdown logic.

Integration with the ozone generator PLC and SCADA for real-time supervision.

Automatic restart and redundancy management in case of pump or sensor failure.

This automation ensures stable cooling capacity, energy efficiency, and continuous protection for sensitive ozone generation components.

Advantages of Longking Closed-Loop Cooling Systems

Closed-Loop Configuration: No external contamination or scaling from raw water.

Redundant Design: Continuous operation with automatic pump switchover.

Compact & Modular: Easy integration with ozone generator skids.

Energy-Efficient Heat Transfer: High-performance plate exchangers reduce energy use.

Safe Operation: Monitored temperature, pressure, and flow parameters.

Custom Design: Adapted to space, climate, and process constraints.

Applications

Longking’s closed-loop cooling systems are used in:

Municipal ozone generation plants – maintaining optimal generator temperatures for stable ozone output.

Industrial oxidation processes – ensuring continuous operation under high ambient temperatures.

Containerized ozone units – compact cooling circuits integrated within modular enclosures.

High-humidity or coastal environments – corrosion-resistant materials for long service life.

With its precision-engineered cooling technology, redundant configuration, and intelligent automation, Longking EnTech Europe guarantees thermal stability and reliability for every ozone generation system.

Our closed-loop cooling units ensure optimal operating efficiency, extended equipment lifespan, and safe, uninterrupted operation — even under demanding environmental conditions.