Ultraviolet Disinfection

UV Disinfection – Chemical-Free, Validated, and Reliable

UV disinfection operates in the 200–300 nm wavelength range, with UV-C energy providing rapid and validated microbial inactivation.

When designed correctly, UV systems achieve high log-reduction values (LRVs) with optimized UV dose and transmittance (UVT) control.

Key Engineering Advantages:

Immediate Disinfection: Bacteria, viruses, and spores are inactivated within seconds as water passes through the UV reactor.

Chemical-Free Process: Eliminates chlorine and other oxidants, avoiding harmful disinfection by-products (DBPs).

Stable & Sustainable Operation: No resistance development, low maintenance, and minimal operational cost (OPEX).

Fully Scalable: Suitable for municipal, reuse, and industrial process water applications.

What is UV-C?

Ultraviolet (UV) Radiation – Engineered Disinfection for Water Systems

Ultraviolet (UV) light is a form of electromagnetic radiation within the 200–400 nm spectrum.

Although invisible to the human eye, it is one of the most effective physical disinfection technologies for water, air, and surface treatment.

Ranges of UV Radiation:

UV-A (315–400 nm): Long wavelength; responsible for photochemical reactions such as tanning and material degradation.

UV-B (280–315 nm): Medium wavelength; contributes to vitamin D synthesis and biological effects on skin.

UV-C (200–280 nm): Short wavelength; delivers strong germicidal action, ideal for inactivating bacteria, viruses, and protozoa in water treatment systems.

UV-C radiation penetrates cell walls and disrupts DNA and RNA replication, preventing microorganisms from reproducing or surviving.

This process occurs instantly, requires no chemicals, and leaves no by-products, making it safe and environmentally sustainable.

UV disinfection is a cornerstone of advanced oxidation and disinfection engineering, offering safe, efficient, and sustainable water treatment—particularly in open-channel systems where continuous, chemical-free operation is essential.

UV-C Disinfection – How It Works

The Science Behind UV-C Technology in Water Treatment Systems

UV-C radiation is germicidal, meaning it effectively inactivates microorganisms such as bacteria, viruses, and protozoa by altering their genetic material.

Unlike chemical oxidants, UV-C acts physically and instantly — no chemical reactions, no by-products, and no formation of resistant strains.

Mechanism of UV-C Inactivation

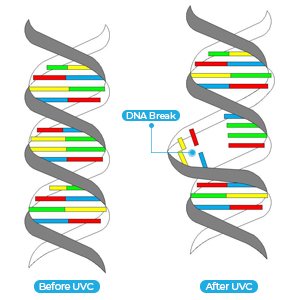

1️⃣ DNA and RNA Disruption

UV-C photons (200–280 nm) penetrate the cell wall and are absorbed by nucleic acids.

This exposure alters the molecular structure of DNA and RNA, preventing microorganisms from replicating or repairing.

2️⃣ Dimer Formation

In DNA-based organisms, UV-C induces thymine dimers — covalent bonds between adjacent thymine bases — interrupting replication.

In RNA-based viruses, UV-C generates uracil dimers, producing structural mutations that block transcription.

Both processes lead to irreversible inactivation of pathogens.

3️⃣ Controlled UV Dose (mJ/cm²)

The level of disinfection achieved depends on UV dose, calculated as intensity × exposure time.

Longking’s open-channel UV systems ensure uniform irradiance and optimized hydraulic design, maintaining effective dose delivery even under variable UVT (ultraviolet transmittance) conditions.

Key Technical Advantages

Instant, Chemical-Free Disinfection: Microorganisms are neutralized within seconds, without chlorine or ozone.

No DBPs or Residuals: Eliminates harmful by-products and avoids the need for post-treatment neutralization.

No Resistance Development: UV is a physical process; microorganisms cannot adapt or evolve resistance.

Operational Reliability: Stable performance over wide UVT ranges (≥65 %) with automated intensity control and lamp monitoring.

Engineering Application

UV-C disinfection provides validated, chemical-free treatment for:

Municipal wastewater tertiary disinfection

Water reuse (reclaimed water)

Industrial cooling and process water

Potable water polishing

Its combination of high UV dose, energy efficiency, and low OPEX makes it the preferred solution for sustainable, long-term operation in open-channel systems.

Longking’s Ultraviolet (UV) Disinfection Systems

Engineered for Open-Channel Water Treatment Applications

Longking Europe designs and manufactures advanced ultraviolet (UV) disinfection systems for water and wastewater treatment.

Our NLQ Series open-channel systems use low-pressure high-output (LPHO) monochromatic lamps (254 nm) to achieve reliable, chemical-free disinfection with optimized energy efficiency.

How It Works

DNA & RNA Inactivation: UV-C photons penetrate microbial cells, disrupting genetic material and blocking replication.

Validated UV Dose: Each reactor is designed to deliver a consistent UV dose (mJ/cm²) according to hydraulic profile, flow rate, and UVT.

Instant Disinfection: Microorganisms are inactivated within seconds — no chemical addition, no residuals, no by-products.

Our UV systems provide log-reduction performance compliant with international validation standards (DVGW, NWRI, and EPA protocols).

Industrial UV Disinfection for Open-Channel Applications

The NLQ Series UV disinfection systems are engineered for municipal, industrial, and water reuse applications where open-channel configuration is preferred.

Key Engineering Benefits:

High Disinfection Efficiency: Optimized UV dose ensures reliable pathogen inactivation even under low UVT conditions.

Hydraulic Optimization: Flow dynamics are carefully modeled to maintain uniform irradiance and minimal head loss.

Scalable Modular Design: Channel-mounted modules allow easy expansion for higher flow capacities.

Automatic Cleaning & Control: Pneumatic quartz sleeve wipers and PLC-based monitoring ensure consistent performance.

Outdoor-Ready Construction: Stainless steel (AISI 316L) frames and IP-rated electrical panels for harsh environments.

Long Lamp Life: >12,000 hours, reducing maintenance and total cost of ownership (OPEX).

Validated Performance: Systems are factory-tested and field-verified for dose accuracy and compliance.

Key Features of Longking’s UV Disinfection Systems

LPHO Amalgam Lamps: High UV output, low energy consumption.

Automatic Wiping System: Maintains sleeve transparency without chemicals.

PLC-Controlled Cabinet: Real-time control, lamp status, and alarm logging.

Dose Regulation: UV intensity automatically adjusted to flow and UVT.

Modular Design: Expandable layout for any flow capacity.

Durability: Designed for outdoor and submerged operation.

Validation: Tested for high performance and regulatory compliance..

Sustainable Engineering in Practice

Longking’s UV technology provides long-term, low-OPEX operation through:

Reduced energy demand (optimized ballast and lamp output).

No chemical handling or storage requirements.

Extended component life and simplified maintenance.

Our systems are built for 24/7 reliability, ensuring safe disinfection in municipal and industrial facilities throughout Europe.

Longking NLQ-H Series – Flexible & Efficient UV Disinfection for Medium & Low Flow Plants

Design Philosophy – Efficiency Meets Reliability

At Longking Europe, each UV system is engineered to achieve optimal hydraulic uniformity, maximum irradiance stability, and minimal head loss.

The NLQ-H Series reflects this philosophy through its horizontal lamp orientation, ensuring:

Uniform UV dose distribution across the full water section,

Simplified maintenance access without removing modules,

Compact footprint ideal for space-constrained installations.

All metallic components are manufactured in AISI 316L stainless steel or higher alloys, ensuring long-term durability even in aggressive environments.

Key Technical Features

Horizontal Lamp Configuration: Efficient hydraulic design with minimal head loss and easy access for maintenance.

Modular Architecture: Expandable layout allows capacity increase or redundancy without re-engineering the channel.

Automatic Pneumatic Cleaning: The sleeve wiping system ensures stable transmittance (UVT) and maintains dose uniformity, eliminating chemical cleaning.

Outdoor-Rated Control Cabinets: Stainless steel (AISI 316L) enclosures with air-conditioned cooling; rated IP54–IP65 for external installation.

PLC + HMI Automation: Intelligent process control system with real-time monitoring, data logging, and remote connectivity (Modbus TCP/IP or Profibus).

Dose Regulation System: Lamp power automatically modulated according to flow rate and UVT to maintain target UV dose and reduce energy use.

System Monitoring and Control

The integrated PLC system provides continuous supervision of:

Operating hours (per lamp and total system)

On/off cycles and lamp ignition count

UV intensity and dose feedback (mJ/cm²)

Fault and defective lamp detection

Flow, temperature, and UVT compensation

Cleaning cycle tracking and alarm management

These parameters are displayed on an intuitive HMI interface for on-site operation and remote diagnostics.

Engineered for Municipal and Industrial Water Treatment Applications

The Longking NLQ-H Series is an advanced open-channel UV disinfection system designed for medium and low-flow plants, typically handling 100 to 3,000 m³/h per channel.

Its compact horizontal architecture allows seamless integration into new facilities or retrofits of existing concrete channels, offering a proven, chemical-free solution for reliable water disinfection.

Developed and manufactured in Europe, the NLQ-H Series combines validated UV dose performance, low operating cost (OPEX), and robust automation, meeting the high standards of municipal and industrial operators.

Operational Advantages

Low OPEX: Intelligent dose control and energy-efficient LPHO lamps minimize running costs.

Chemical-Free Maintenance: Pneumatic cleaning prevents fouling and maintains consistent UV output.

Easy Retrofit: Horizontal design and modular construction simplify installation in existing channels.

Robust Outdoor Design: Weather-resistant materials and cooled control cabinets guarantee continuous operation under all climates.

European Engineering: Designed and validated under Longking Europe’s quality framework, ensuring traceability and reliability.

Applications

The NLQ-H Series is ideally suited for:

Municipal tertiary wastewater disinfection (urban WWTPs)

Industrial process and cooling water

Water reuse and reclamation plants

Potable water polishing systems

Sustainable Disinfection for the Future

By eliminating chemicals and reducing power demand, the NLQ-H Series contributes to sustainable water management and supports SDGs 6 and 14 (Clean Water and Life Below Water).

With its modular design, validated performance, and low life-cycle cost, the NLQ-H Series is the preferred choice for modern UV disinfection facilities across Europe.

Longking NLQ-HPV Series – High-Power Vertical UV Disinfection for Large-Scale Water Treatment Plants

Maximum UV performance, compact footprint, and proven engineering reliability

When scale and performance converge, precision becomes critical.

Engineered by Longking Europe, the NLQ-HPV Series redefines open-channel UV disinfection for high-flow and large-capacity water treatment plants.

Its 800 W high-power vertical lamps deliver exceptional UV dose performance — achieving the same disinfection effect with fewer modules, smaller channels, and lower operating costs.

Developed from the proven NLQ-V platform, the HPV range integrates higher intensity lamps, advanced electronic control, and robust modular construction, ensuring long-term reliability under continuous operation in municipal and industrial environments.

Design Philosophy – Power and Precision in Vertical Form

Every element of the NLQ-HPV Series has been engineered around a single principle: maximum UV performance with minimum complexity.

The vertical lamp configuration provides:

Superior hydraulic exposure and UV dose uniformity through optimized cross-flow dynamics.

Compact channel footprint, ideal for retrofit or space-restricted installations.

Simplified maintenance, as lamps can be removed without dismantling the module.

Reduced infrastructure cost, thanks to fewer modules and smaller civil works.

This architecture transforms the traditional open-channel UV approach into a high-density, low-OPEX solution for modern treatment plants.

Key Technical Features

800 W High-Power Amalgam Lamps: Deliver intense irradiance for higher doses and reduced module count.

Vertical Cross-Flow Lamp Design: Ensures even dose distribution and optimal hydraulic conditions at high flow velocities.

Automatic Pneumatic Cleaning System: Maintains sleeve transparency and UVT without chemicals, ensuring constant performance.

PLC + HMI Automation: Integrated control with real-time monitoring of UV dose, lamp status, and cleaning cycles.

Outdoor-Rated Stainless Steel Cabinets: AISI 316L enclosures with active cooling for harsh environments (IP54–IP65).

Intelligent Dose Regulation: Lamp output automatically adjusted to maintain target UV dose while minimizing energy consumption.

Scalable Modular Design: Expandable system architecture enables phased capacity increase or redundancy without major redesign.

Intelligent Monitoring and Control

The HPV range integrates advanced PLC supervision for full system visibility and operational reliability.

Monitored parameters include:

Operating hours per lamp and system

Lamp ignition cycles and failures

UV intensity and dose (mJ/cm²)

Flow and UVT compensation

Temperature and cleaning cycle tracking

Alarm history and diagnostic logs

Data are displayed via a touchscreen HMI and available for integration into SCADA systems via Modbus or Profibus communication.

Operational Advantages

Higher Power, Fewer Modules: Achieves target UV dose with up to 40 % fewer lamps compared to standard systems.

Compact Civil Design: Reduces channel width and construction costs.

Continuous Automatic Cleaning: Maintains optimal transmittance with minimal maintenance.

Reduced Energy Demand: Adaptive power control minimizes consumption at low flows.

Reliable Outdoor Operation: Stainless construction, air-conditioned cabinets, and IP protection ensure year-round operation.

European Engineering Quality: Designed, assembled, and validated in compliance with EU standards.

Applications

The NLQ-HPV Series is ideally suited for:

Municipal wastewater treatment plants – tertiary disinfection before discharge or reuse.

Water reuse and reclamation facilities – large flow and variable UVT applications.

Industrial process and cooling water treatment – robust operation under demanding conditions.

Retrofit projects – replacing legacy systems with minimal structural modifications.

Sustainable High-Performance Disinfection

By combining chemical-free operation, reduced energy use, and extended component life, the NLQ-HPV Series supports sustainable water management and contributes to the UN Sustainable Development Goals (SDGs 6 & 14).

Fewer lamps, less maintenance, and lower OPEX mean cleaner water with a smaller footprint — both operational and environmental.

Why Choose NLQ-HPV

Because it delivers more power, more certainty, and more efficiency — with less infrastructure, less downtime, and less energy.

Built to perform.

Validated to endure.

Engineered for the next generation of water treatment.