Longking Ozone Generators

Industrial & Municipal Ozone Generators — High-Efficiency Oxidation Systems

At Longking EnTech Europe, we design and manufacture advanced ozone generation systems for municipal and industrial water treatment, air purification, and advanced oxidation processes (AOPs).

Our technology is based on over two decades of experience in corona discharge (CD) systems, combining precision glass dielectrics, IGBT-controlled high-frequency power supplies, and intelligent automation.

This results in superior ozone yield, outstanding reliability, and optimized energy performance across all applications.

Why Ozone? — The Benchmark in Oxidation and Disinfection

Ozone (O₃) is one of the strongest oxidants known (E° = 2.07 V), significantly more powerful than chlorine or hydrogen peroxide. Its decomposition leaves only oxygen, making it an environmentally clean and residue-free disinfectant.

In water and wastewater treatment, ozone:

Destroys viruses, bacteria, and protozoa more effectively than chlorine.

Oxidizes micro-pollutants, color, and odor compounds.

Improves biodegradability (BOD/COD ratio), facilitating downstream biological processes.

Eliminates the need for chlorine, avoiding formation of trihalomethanes (THMs) and other byproducts.

Supports AOP systems when combined with UV or H₂O₂ for enhanced oxidation kinetics.

For municipalities, ozone ensures safe drinking water and high-quality effluent reuse.

For industry, it guarantees cleaner processes, lower chemical dependency, and stronger environmental compliance.

The Science of Ozone Generation — Precision Corona Discharge

Longking’s ozone generators employ double micro-gap corona discharge with borosilicate glass dielectrics, ensuring maximum conversion efficiency and long operational life.

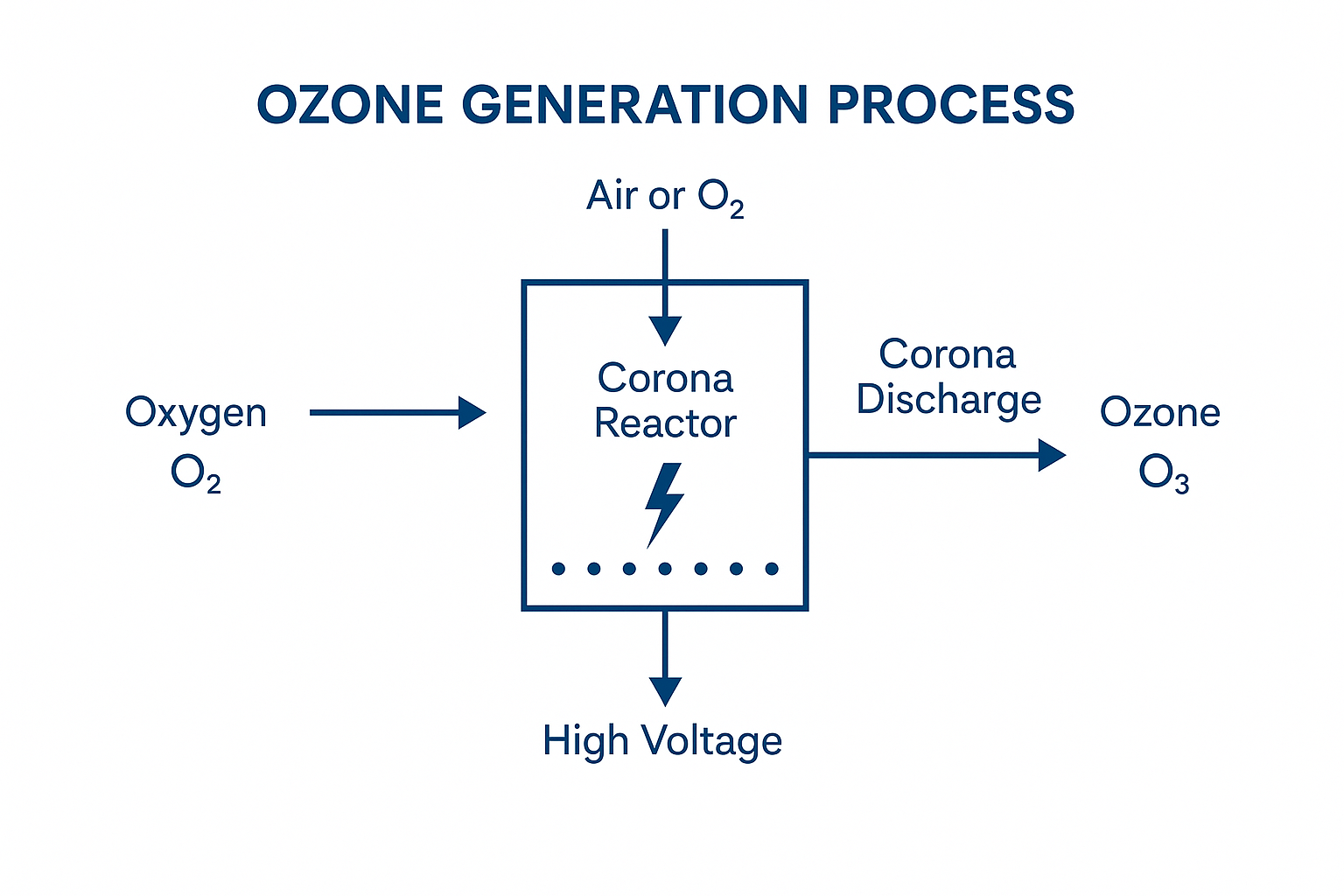

Generation Principle:

Oxygen (O₂) enters the discharge chamber through a controlled flow system.

A high-frequency electric field (5–10 kHz) is applied between stainless steel electrodes separated by a dielectric glass barrier.

The electrical energy creates a cold plasma that splits O₂ molecules into atomic oxygen (O).

These atoms recombine with O₂ to form ozone (O₃).

This design achieves high concentrations (up to 296 g/Nm³) while minimizing parasitic heat losses and maintaining energy efficiency ≤ 7.5 kWh/kg O₃ under standard operating conditions.

Two Complementary Series — Tailored to Every Application

Core Features:

Double Micro-Gap Discharge with high-purity borosilicate dielectrics.

Reactor Modules in Horizontal Configuration for uniform cooling and accessibility.

Closed-Loop Water Cooling System with plate heat exchangers and expansion vessel.

Independent Power Supply Units (PSUs) per module, ensuring redundancy and 24/7 uptime.

Energy Optimization Algorithms (DSP + PDM) maintaining high ozone yield even under variable load.

Certified under CE & ISO 9001, fully compliant with EU electrical and safety standards.

NLO LITE Series — Compact & Intelligent Ozone Systems

The NLO LITE Series delivers the same Longking engineering excellence in a smaller footprint, ideal for medium-scale municipal plants, reuse facilities, or industrial pilot applications.

Key Benefits:

Capacities from 500 g/h to 1.5 kg/h.

Air or Oxygen Feed with integrated dryer or PSA unit.

Vertical or Skid Configuration, ready-to-install.

Forced-Air or Water Cooling, depending on model.

PLC-based Automatic Control, HMI display with multi-language support.

Maintenance-Friendly Design — quick access to dielectric tubes and sensors.

NLO Series — High-Capacity Modular Systems for Municipal & Industrial Use

The NLO Series is designed for large-scale water treatment plants and heavy-duty industrial oxidation processes, offering scalable modular architecture from 1 kg/h to 160 kg/h of ozone production.

Performance:

Concentration: 150–296 g/Nm³

Efficiency: ≤ 7.5 kWh/kg O₃

Feed gas: LOX / PSA Oxygen

Cooling water: 25 °C closed loop

Minimum uptime: > 90% continuous operation

Applications:

Small wastewater and reuse plants

Food & beverage sanitation

Pharmaceutical and cosmetic production

Containerized or modular pilot systems

Advanced Power Electronics — IGBT Technology for Efficiency and Control

Longking’s power units integrate IGBT (Insulated Gate Bipolar Transistor) modules, managed by a DSP (Digital Signal Processor) to ensure high precision and dynamic energy regulation.

Key Advantages:

Pulse Density Modulation (PDM) for optimized discharge stability.

Low Cooling Requirement — no external air conditioning needed in most models.

Automatic Fault Detection and Converter Diagnostics.

High Power Factor (>0.95) ensuring electrical efficiency.

Enhanced Dielectric Protection through real-time monitoring.

This ensures a perfect match between electrical control and plasma discharge, minimizing downtime and maximizing yield.

Automation & Control — Intelligent Operation Made Simple

All ozone systems include a fully integrated PLC + HMI platform, designed for real-time monitoring, smart regulation, and remote accessibility.

Control Capabilities:

Real-time control of O₂ flow, ozone concentration, temperature, and pressure.

SENTINEL Remote System – cloud-based monitoring and data logging.

Multi-language interface for global operability.

SCADA-ready communication (Modbus/TCP, Ethernet).

Predictive alarms for preventive maintenance.

Automation translates into stable ozone output, optimized oxygen use, and reduced operator intervention — essential for critical municipal and industrial applications.

System Architecture & Integration

Each Longking ozone system is delivered as a complete skid-mounted solution, tested and pre-assembled for plug-and-play installation.

Main Components:

Ozone Reactor with Dielectric Assembly

High-Frequency Power Supply

Cooling Circuit (Heat Exchanger + Pumps + Valves)

Flowmeters, Pressure Gauges, Thermometers

Gas Analyzer & Safety Interlocks

Catalytic Ozone Destructor

Electrical Cabinet with PLC/HMI Interface

This configuration simplifies commissioning, reduces installation time, and guarantees full compatibility with auxiliary equipment.

Safety, Reliability & Long-Term Stability

Safety is built into every system through multi-layer protection:

UFF Technology (Fused Dielectrics): each tube independently protected.

Overcurrent / Overtemperature Control in real-time.

Automatic Shutdown upon abnormal discharge conditions.

Ground Fault and Leakage Detection integrated in PSU.

Catalytic Destructor converting residual ozone to oxygen.

Our systems are designed for continuous 24/7 operation, meeting the most stringent EU industrial safety standards.

Applications & Use Cases

Municipal Drinking Water Plants (DWTPs)

Wastewater Treatment & Reuse (WWTPs)

Advanced Oxidation Processes (AOPs)

Industrial Process Water (Textile, Petrochemical, Pulp & Paper)

Cooling Water & Legionella Prevention

Food, Beverage & Pharma Sanitation

Air & Odor Treatment

Aquaculture & Fish Farming

From large-scale municipal infrastructures to precision-engineered industrial systems, Longking EnTech offers reliable, sustainable, and intelligent ozone generation.

Partner with Longking EnTech Europe

With over 20 years of engineering experience, in-house manufacturing, and European-based support, we deliver solutions that exceed performance expectations.

Our expertise covers:

Feasibility studies and pilot trials

System integration and commissioning

Remote monitoring and after-sales service

Custom design to meet specific process or space constraints

Contact our engineering team for customized ozone systems that combine efficiency, safety, and innovation.